Fat Traps and Grease Separators for Wastewater Solutions

At Spans Envirotech, we offer advanced Fat Traps and Grease Separators designed to combat fat, oil, and grease (FOG) buildup in wastewater. Our solutions prioritize efficiency and sustainability, making them ideal for commercial kitchens, food processing plants, and other industries with high FOG output.

Our Proficiency

With decades of experience, our team delivers custom-engineered grease management systems that adhere to environmental regulations while enhancing operational efficiency and safety.

What are Fat Traps and Grease Separators?

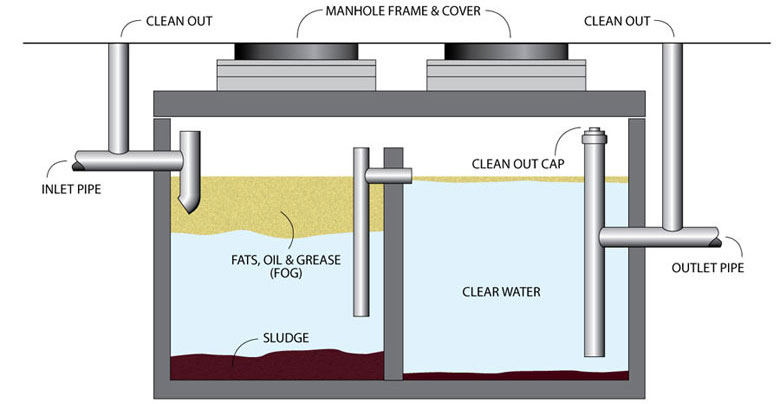

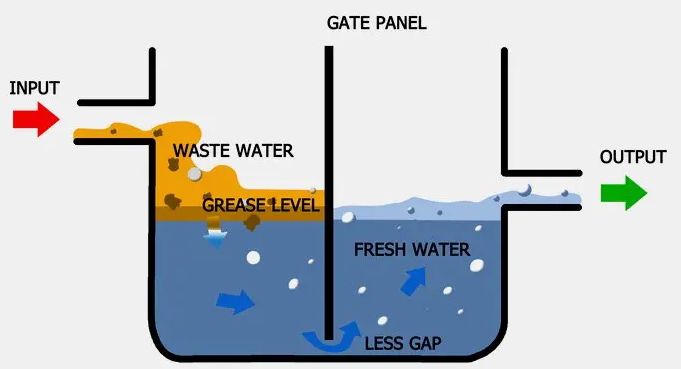

Fat traps and grease separators are devices designed to remove fats, oils, and grease from wastewater before it enters the drainage system. They prevent blockages, protect water quality, and ensure compliance with regulations. Our systems range from passive grease traps for small operations to advanced automatic units for high-volume facilities.

- Passive Grease Traps: Gravity-based systems that separate FOG from water.

3. Hydromechanical Grease Interceptors: High-efficiency systems combining flow control and separation for larger operations.

2. Automatic Grease Removal Units (AGRUs): Self-cleaning units designed for continuous operation.

4. Biological Grease Treatment: A solution that uses microorganisms to break down grease, reducing maintenance needs.

Benefits of Our Grease Management Solutions

Our grease management solutions offer a wide range of benefits that go beyond effective FOG removal. By ensuring environmental protection, our systems safeguard ecosystems and water sources. They also enhance system longevity, reducing blockages and wear on plumbing infrastructure. Additionally, our solutions lead to cost efficiency, cutting down on expensive repairs and maintenance. We prioritize health and safety, preventing hazardous grease buildup in work environments, while promoting sustainability by enabling the recovery of FOG for reuse in eco-friendly applications like biodiesel production.

Environmental Protection: Prevents harmful FOG from entering waterways, ensuring compliance with environmental regulations.

Cost Efficiency: Minimizes expensive plumbing repairs and emergency interventions, offering long-term savings.

System Longevity: Reduces blockages and corrosion in drainage systems, extending their lifespan.

Health and Safety: By preventing hazardous grease buildup, our systems contribute to a cleaner, safer environment for workers and the public

Why Choose Us?

Tailored Solutions: We develop customized grease management systems that are specifically designed to address the unique needs and operational demands of your facility, ensuring maximum efficiency and effectiveness.

Expert Support: Our comprehensive training programs and 24/7 technical support ensure that your team can operate and maintain the systems proficiently, with assistance always available when needed.

Innovative Technologies: We employ the latest advancements in FOG management, delivering cutting-edge designs that enhance efficiency, reduce operational costs, and optimize performance.

Regulatory Compliance: Our systems meet and often exceed the highest environmental and wastewater management standards, ensuring full regulatory compliance and peace of mind.

Our WasteWater Treatment Process:

- Initial Assessment: We conduct an in-depth evaluation of your facility’s grease management requirements, including FOG volume, kitchen operations, and existing infrastructure.

- Custom Design: Our engineers develop a tailor-made system to maximize FOG separation while ensuring seamless integration with your plumbing.

- Installation: Professional installation guarantees that your grease separator operates at peak performance from day one.

- Regular Maintenance: We offer scheduled servicing to keep the system functioning optimally, avoiding potential blockages.

- Waste Recovery: Our systems allow for FOG to be collected and repurposed, reducing waste and promoting sustainability.

- Ongoing Monitoring: Equipped with advanced monitoring systems, our grease traps allow real-time tracking of performance and grease accumulation.

- Comprehensive Training and Support: We provide hands-on training for your staff, ensuring proficient system operation and routine maintenance procedures.

Additional Resources

Custom Solutions: Tailor your grease management system to meet the exact needs of your business.

Sustainability Practices: Learn how your facility can benefit from waste recovery and contribute to global sustainability goals.